Introduction

ROBUS ® Pumping solutions have demonstrated record of outstanding performance and reliability on various applications, duties and pumping scenarios. Our brand success is grounded in the solutions that cover wide spectrum of aspects, straightened by the immediate availability of our parts.

We succeed only when it is a successful solution for our clients, as it is the case in the following notable case studies:

ERG FRONTIER – LAROX FEED PUMPING SOLUTION

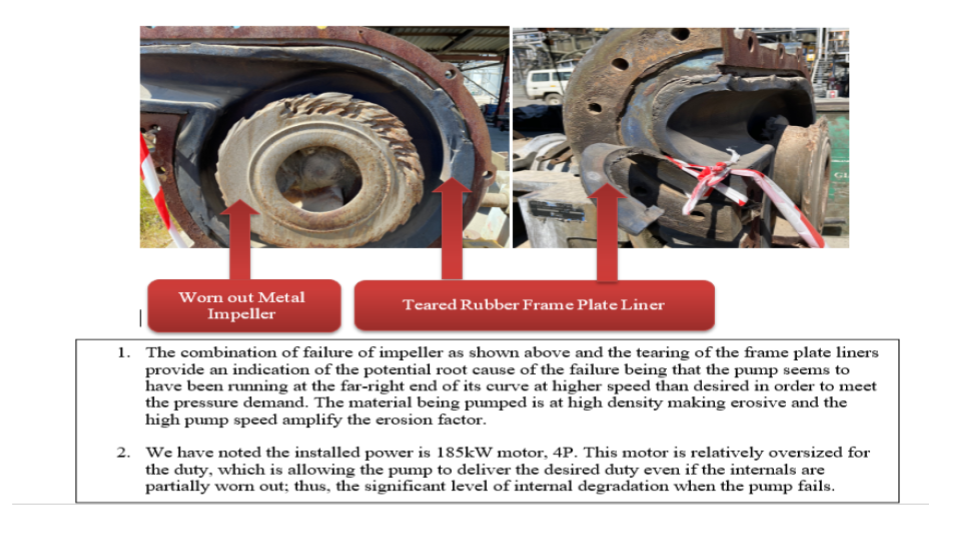

Axis Mining Team of Experts conducted multiple site visits to ascertain the reasons behind the continuous failures of the Larox Feed Pumps.

Axis Mining Team formulated a custom made solution by incorporating mitigating factors in our ROBUS pumps design, in addition to the selection of adequate pump size and speed ranges, while delivering the desired flow rate and discharge pressure.

ERG FRONTIER – LAROX FEED PUMPING SOLUTION

Axis Team offered the followed solutions which have since then implemented with success:

- Improved Impeller Tip Speed

- Improved impeller and internal materials

- Optimized control system of the flow and feed tank levels

KAMOTO COPPER COMPANY – VARIOUS PUMPING SOLUTIONS

Axis Mining Team has investigated the root cause failure for the multiple sheared shafts on the thickeners overflow solution pumps after taking some samples and carried out detailed lab analysis.

Axis Team offered the following solutions:

- Substituted the stainless-steel material grade of the shaft with Robus upgraded SS316L composite

- Optimized the control system and speed set points

- Improved the mechanical seal configuration

KALUMBILA MINE – SUMP PUMP & POND TRANSFER PUMPS SOLUTIONS

Axis Team completed the full Engineering and detailed design for the installation of new transfer pumps at the event pond, to avoid pond overflow, and have the slurry return back to the mill sumps with an option to be discharged at the tailing tanks.

BARRICK LUMWANA – TAILING PUMPS SOLUTIONS

Axis Team has investigated and offered technically sound and practical solution of the failure to meet desired flow rate on the tailing

pumps at Lumwana by offering upgraded pump size with heavy duty bearing assembly that doesn’t require increase on installed power.

TENKE FUNGURUME – CYCLONE FEED PUMPS SOLUTIONS

Axis Team has conducted multiple site visits and audited to the existing problematic Cyclone feed circuits, which resulted in offering efficient pumps that are operating at the optimum speed and within the BEP of their respective curves.

TENKE FUNGURUME – LEACH FEED PUMPS SOLUTIONS

ROBUS ® pumps solutions has substituted existing problematic leach feeding application by offering and installing the correctly and custom-make products. We are proud of the outcome of the application analysis and solutions offered that addressed the core issues at hand, thus increasing operating time and saving costs for our client.

TENKE FUNGURUME – CHEMICAL PUMPS SOLUTIONS

ROBUS chemical pumps have proven to be the best and premium choice of pumps when it comes to complex and highly corrosive chemical solution environments.

Through the in-depth analysis and peculiar selection of the appropriate acid and erosion resistant materials, in line with the client equipment in terms of operations parameters, ROBUS Chemical pumps have recorded success in various chemical and solution application, which is recognized by our client.

We drove the cost down and increased the efficiency of the chemical and solution circuits at Tenke Fungurume.

ONLY ROBUS BESPOKE SOLUTIONS

KANSANSHI MINE – LEACH DESCENDING PUMP SOLUTIONS

ROBUS ® pumps concurred the severe leach descending pump application at Kansanshi mine where the combination of large particle sizes that run at fast speed and lower pH of acidic materials destruct the internals of the pumps regularly .

ROBUS® custom made solutions offers solutions not only to the problem at hand but at the same prevents other destructive events that the applications manifest in the pump operations with great success.

KANSANSHI MINE – LEACH DESCENDING PUMP SOLUTIONS

ROBUS ® pumps concurred the severe leach descending pump application at Kansanshi mine where the combination of large particle sizes that run at fast speed and lower pH of acidic materials destruct the internals of the pumps regularly .

ROBUS® custom made solutions offers solutions not only to the problem at hand but at the same prevents other destructive events that the applications manifest in the pump operations with great success.